Wet Scrubber Control in Biomass Boilers

The challenge

Wet scrubbers remove particles from industrial gases, keeping contamination below 50% of the legal limit. Their efficiency depends on direct contact between the gas and the liquid, achieved through constant flow and pressure spraying. Key performance indicators include: constant differential pressure, stable liquid and gas flow rates, gas outlet temperature (in thermal processes), and liquid pH (related to the removal of acid gases).

The customer required a system to control the operation of two gas scrubbers in high-pressure biomass boilers. This equipment replaced the electrostatic precipitators that were initially installed.

The solution

Control system for gas scrubber, for emissions control, with interface to existing DCS.

Implementation of a control system for a gas scrubber and auxiliary systems

The project included:

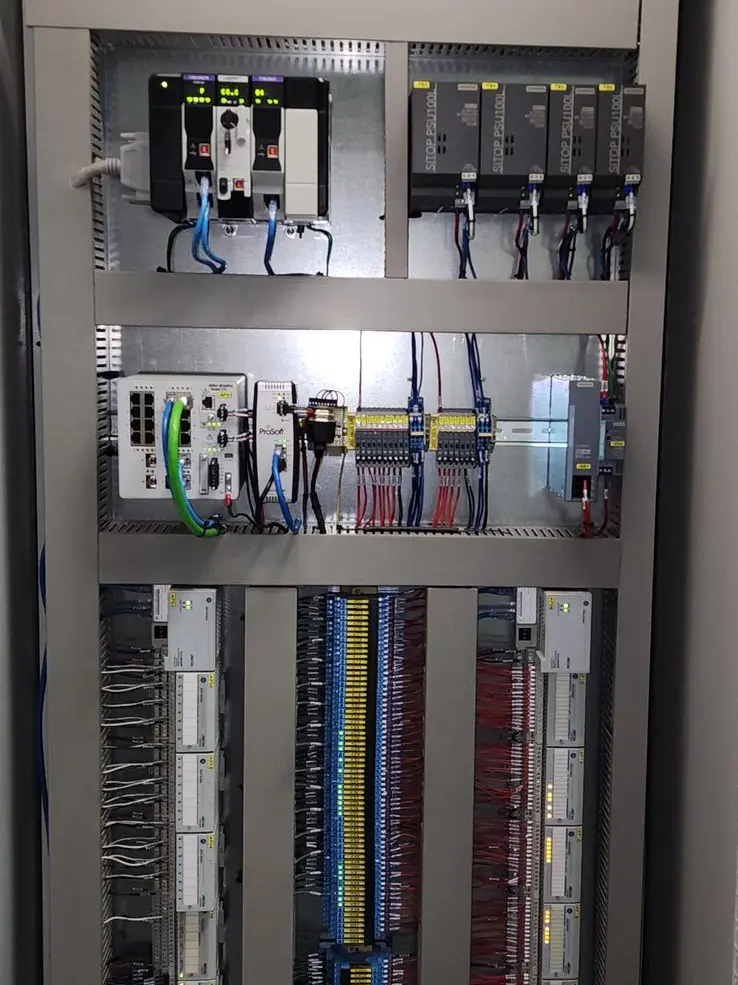

- Control panel consisting of a Contrologix PAC, communication interfaces, and redundant power supplies.

- Remote I/O station with more than 120 digital and analog signals.

- Control of pump motors, ash conveyors, and induced draft fan with medium voltage frequency converter.

- Integration of temperature, pressure, vibration, and speed sensors.

- Integration of modulating electric actuators for fan dampers.

- Industrial switches for connection to DCS..

The benefits

Emissions below legal limits, full integration with usable infrastructure, reliability, and operational continuity.

- Ensured environmental compliance, keeping emissions well below regulatory limits.

- Greater reliability and operational safety by automating the operation of critical equipment.

- Real-time monitoring of process conditions, reducing risks and avoiding unexpected downtime.

- Maintenance optimization, with sensors that allow you to anticipate failures and reduce costs.

- Scalability and flexibility, thanks to modular architecture and industrial communication networks.

Impact on the plant

Increased plant and environmental safety, efficiency, increased automatic emission control, and extended equipment service life.

- With this project, the plant strengthened its environmental and regulatory commitment while increasing operational efficiency. Automating the emissions system not only reduced compliance risks but also improved production continuity and equipment lifespan.

- Today, the plant has a robust, scalable, and reliable solution that supports both its productivity and environmental responsibility.

2022 Boiler#2 Wet Scrubber Control