New infrastructure for Ethernet process network

The challenge

The client interconnected its different process areas with a 100 Mbps ring network. This topology generated bottlenecks, excessive latency, and delays in updating information. The infrastructure did not respond current data traffic demands or the IT/OT integration necessary to ensure operational continuity and safety at the plant.

A mesh topology network architecture was implemented, with redundant links and high-availability industrial switches. The speed of the access switches was increased from 10/100 Mbits to 1 Gbit on all ports, with the possibility of growing to 10 Gbps. On the distribution switches, the link speed to the data center was increased from 1 to 10 Gbits.

Main actions:

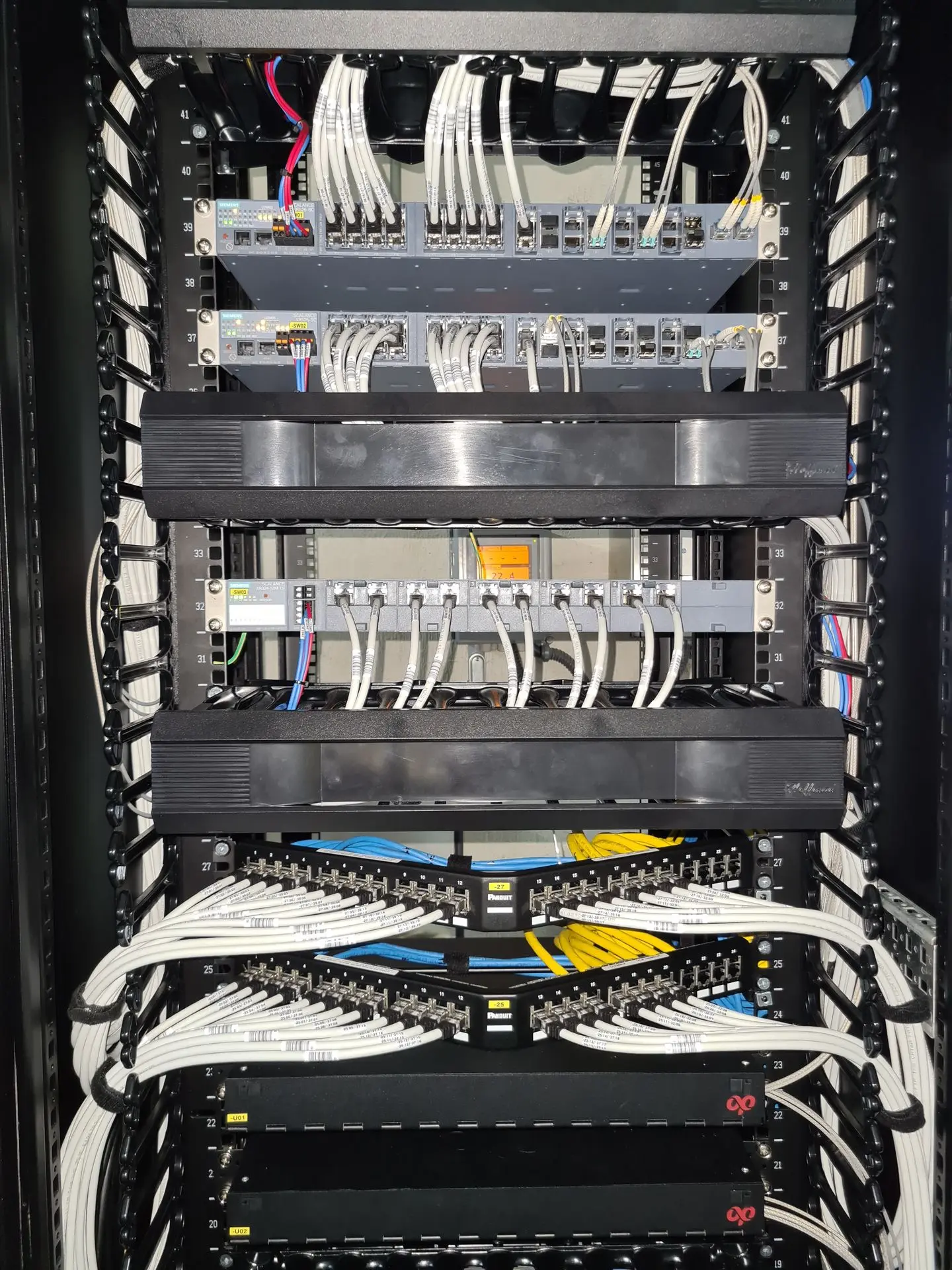

- Installation of cabinets with industrial switches and redundant power supplies in different areas of the process.

- A new infrastructure was channeled for the fiber optic network and structured cabling, suitable for industrial environments.

- SCALANCE XR526 and XR324 industrial switches, configured with advanced redundancy and security protocols.

- Redundant fiber optic and copper links to ensure continuous availability.

- State-of-the-art structured cabling, with optical validation under EIA/TIA 568 standard.

- Optimized IT/OT integration for reliable communication between plant and administrative systems.

The benefits

Elimination of delays due to network congestion, reduction of latency to a minimum, timely availability of information, and integration with the corporate network.

- 10 times faster than the previous network infrastructure.

- Bottlenecks and network congestion were avoided.

- High availability and lower latency, with agile and timely visualization and refreshing of screens and process variables.

- Secure and robust infrastructure, designed for critical industrial environments.

- Scalability to mesh topology and Industry 4.0 projects.

- Optimized IT/OT integration, connecting the plant and data center reliably and securely.

Impact on the plant

Operational continuity, greater security, and scalability, in addition to support current data traffic demand and IT/OT integration.

With this new infrastructure, the customer has a modern, secure network that is ready for future growth, ensuring operational continuity, fast data traffic, and the digital integration of key processes.

2022 Process Ethernet Network