Hydraulic Motor Control Sugarcane Mills

The challenge

The extraction area (mills) of a sugar mill uses hydraulic actuators from a renowned manufacturer to move the mill hammers. The control stations were composed of PLCs and HMIs that had already been discontinued. As the equipment was supplied by the original manufacturer, the price of replacements was high due to the inclusion of proprietary software. In summary, the following problems arose:

- Risk of operational interruptions in critical equipment.

- Difficulties with technical support from the original manufacturer.

- Spare parts stock different from the technology used in the plant.

- Limitation in the signals available for monitoring; the interface with the grinding control system was via wired inputs/outputs.

A complete migration of the control system was carried out, replacing the existing technology with a modern, secure, and scalable platform.

Including:

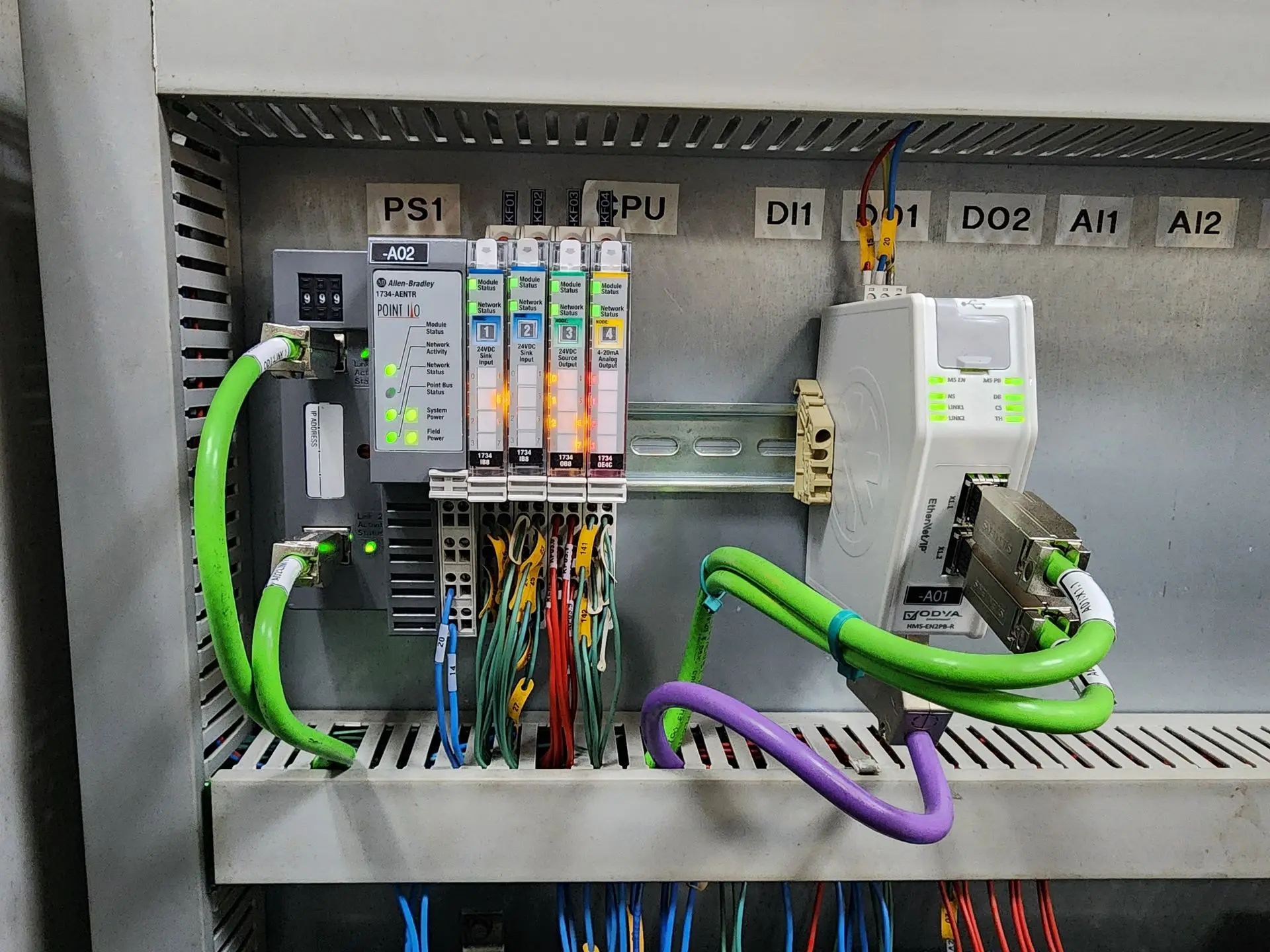

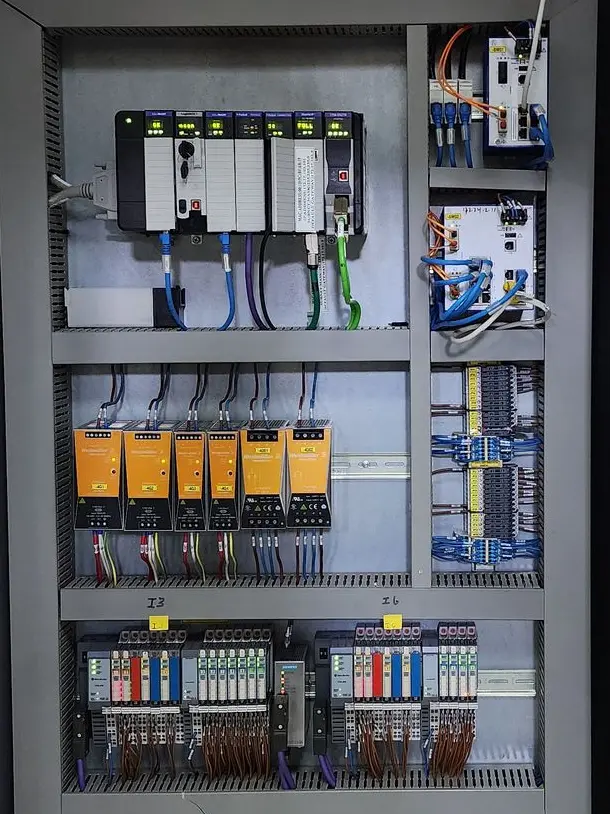

- Integration of the hydraulic actuator operation console into the Allen Bradley ControlLogix PLC for centralized control of each mill.

- Integrated hydraulic actuator function into the main PLC: Start/Stop, Speed Regulation, Level/Float Control of the hammers, protections.

- Monitoring and diagnostics: alarms and historical records of the main variables in the new HMI terminals..

- Implementation of new functions required by the end user.

- Inclusion of individual emergency stops per mill for greater safety.

- Development of an application integrated with the plant SCADA.

- Updating of documentation in digital and printed format, ensuring traceability and future support.

The benefits

Reduced risk of operational failures, improved safety processes, and greater technical support for modern equipment.

With the migration, the customer achieved:

- Greater safety and operational continuity in the mills.

- Real-time monitoring of all critical variables.

- More efficient and safer operation, integrating new functions and emergency interlocks.

- Full ownership of the software and flexibility for future expansions.

- Modern and intuitive interface, simplifying operation.

- Compliance with international control and safety standards.

Impact on the plant

Increased safety, efficiency, and scalability due to a production infrastructure that is easier to operate and less expensive to maintain.

The upgrade ensured a robust, secure, and future-proof control system, reducing the risk of failure, improving efficiency, and extending the service life of the mills.

2024 Hägglunds Control Desk Upgrade