Automation of Sugarcane Feeding Tables

The challenge

The sugar mill had a grinding control system that protected against overloads in the cane preparation equipment. However, the feeding of the dosing tables and the auxiliary conveyor was done manually, which caused variations in the flow of cane to the factory.

This resulted in:

- Instability in the grinding process.

- Dependence on the skill of the operators.

- Risk of gaps or overfeeding.

- Loss of time and reduced efficiency in the mill yard area.

The challenge was to fully automate the cane feeding process, ensuring a stable, safe, and flexible flow to response to the growing demand for production.

The solution

Installation of dynamic scales to control the unloading of tables onto cane conveyors.

Installation of three dynamic scales to control the unloading of tables onto cane conveyors.

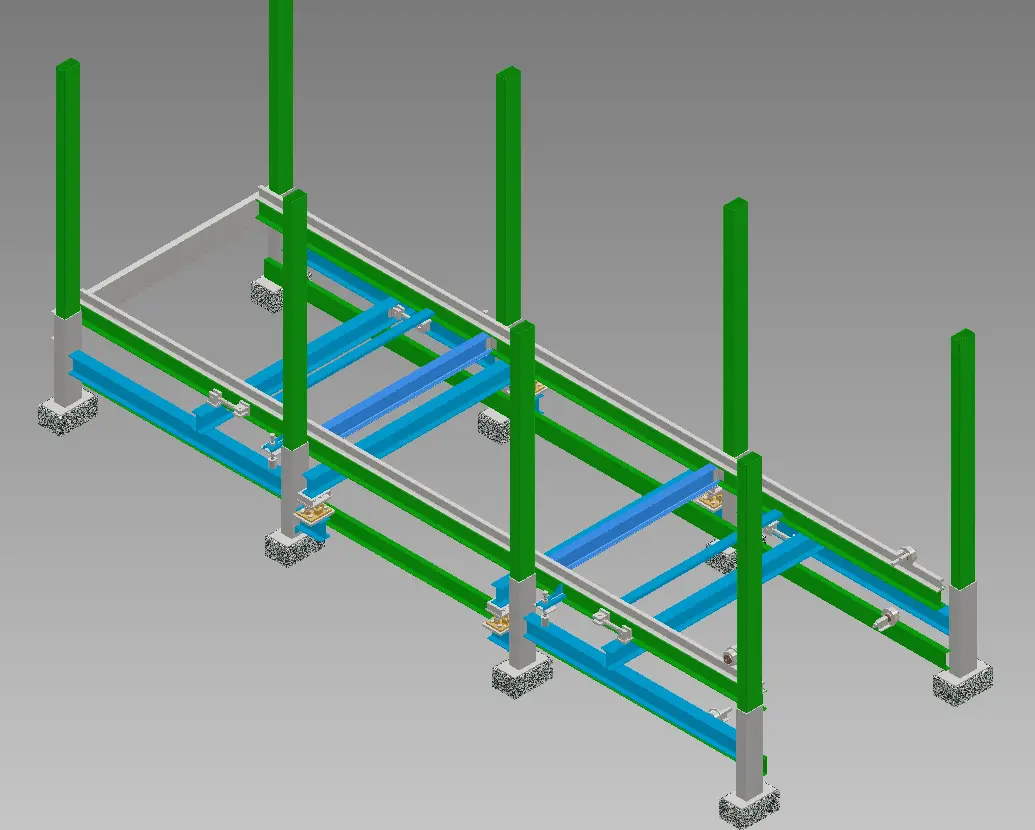

A special frame was designed and manufactured for each scale, built to fit the conveyor. The objective, in addition to supporting the load cells, was to reinforce the structure of the conveyor and eliminate axial and transverse force components, allowing only the vertical components of the weight to act on the cells.

The system also included:

- 3 BW500 electronic indicators for dynamic weighing and electronic balancing of the weighing bridge (no summing boxes required)

- Ultrasonic level transmitters for measuring the height of the cane bed.

- Expansion of the Profibus DP network in fiber optics and copper, integrating drives, scales, and control islands.

- Complete engineering services: PAC programming, HMI screen configuration, electrical and mechanical installation, scale calibration, and FAT/SAT testing.

- Training for operating and maintenance personnel to ensure proper adoption of the system.

The benefits

Automatic control of table discharge. Excellent precision in cane weighing and weight distribution in the conveyor.

- Stability and continuity in grinding, eliminating gaps in feeding.

- Increased productivity by reducing downtime and increasing grinding capacity.

- Protection of preparation equipment, preventing overloads.

- Operational flexibility, allowing feed ratios between each table to be defined.

- Adaptation to the type of cane harvest, ensuring reliability in all scenarios.

Impact on the plant

Reduction of downtime and increased production efficiency.

With the implementation of this system, the sugar mill achieved the following:

- Automation of a critical process, eliminating dependence on manual operation.

- Optimization of efficiency in the mill yard field, ensuring a continuous flow of cane to the factory.

- Increased production capacity and a more robust response to demand.

- Consolidation of a modern, secure, and scalable control system, aligned with international automation standards.

This project marked a turning point in the operation of the sugar mill, strengthening its competitiveness and reliability in the grinding process. The weighing accuracy is far superior to other systems implemented by third parties.

The combination of excellent mechanical design and appropriate electronics, together with ALETLER's engineering, was the key to success.

2021 Cane Feeding Tables and Conveyor Control System