Upgrade of the Continuous Centrifuge Control System of “A”

The challenge

The control system for continuous mass centrifuges “A” operated with obsolete PLCs (Allen Bradley SLC 500) and outdated HMI screens, which posed a risk to the reliability, safety, and efficiency of the process. In addition, the centrifuge motors had delta/star starters, which prevented the machines from starting under load, the contactors were worn, and the electrical panel was generally in poor condition.

The plant needed a solution that would modernize control, reduce risks, and ensure operational continuity.

The solution

Comprehensive modernization of the centrifuge control and start-up system.

We implemented a comprehensive modernization of the control system, and motor control was migrated to high-tech soft starters.

This included:

- Technology migration: replacement of SLC 500s with Allen Bradley CompactLogix 5370-L1, with integration of remote Point I/O islands in Ethernet/IP network.

- Advanced visualization: replacement of Proface HMI with 10.4" PanelView Plus 7, with a more user-friendly interface and improved process monitoring.

- Control optimization: updating of logic in Studio 5000 and adjustment of control loops for greater safety and efficiency.

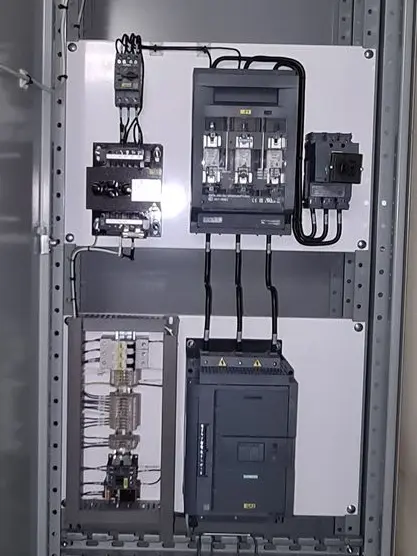

- Motor protection: supply and installation of three Siemens Sirius 3RW52 soft starter panels, with Ethernet/IP communication and advanced overload and short-circuit protection.

The benefits

Modernized system, controlled starts, equipment protection, and more real-time information.

- Controlled and safe starts, reducing mechanical stress on motors and coupled equipment.

- Ability to handle variable load conditions, the machine could be loaded

- Greater reliability and availability by replacing obsolete equipment with modern, scalable technology.

- Comprehensive protection of motors and panels, reducing failure risks and maintenance costs.

- Greater diagnostic capability thanks to new HMI interfaces and standardized Ethernet/IP communication.

Impact on the plant

Increased control, risk reduction, and assurance of operational continuity.

With this modernization, the sugar mill achieved a robust, efficient, and future-proof control system that guarantees operational continuity, improves equipment and operator safety, and ensures production stability. The plant now has more reliable centrifuges, with lower energy consumption and longer motor life, strengthening the competitiveness of the industrial process.

2021 Continuous Centrifuge Controls Upgrade